A distinct segment within the welding equipment market is seeing increased attention with the rise of the portable mini welding machine. This category of equipment, characterized by its compact size, reduced weight, and often multi-process capability, is attracting a broad user base that includes hobbyists, DIY enthusiasts, artists, and professionals requiring a tool for light-duty repairs and fabrication. The appeal of the portable mini welding machine lies in its ability to offer genuine welding functionality in a package that emphasizes accessibility and convenience for non-industrial settings.

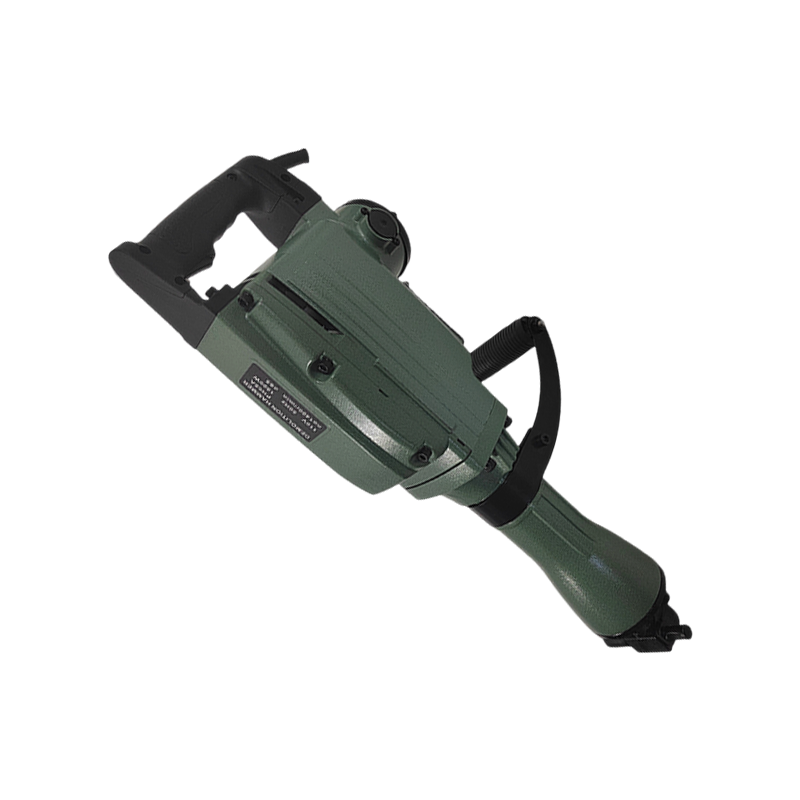

The defining feature of a portable mini welding machine is its physical profile. These units are designed to be significantly smaller and lighter than traditional industrial welders, making them easy to transport in a vehicle, carry to a work site, or store in a limited space like a garage or workshop. Despite their size, a modern portable mini welding machine frequently incorporates inverter technology, allowing it to deliver a stable welding arc while operating on standard household single-phase power. This combination of portability and adequate power makes the portable mini welding machine a practical solution for a wide array of small-scale projects.

The functional range of a contemporary portable mini welding machine is another key to its growing adoption. Many models are engineered as multiprocess units, capable of performing common welding tasks such as Stick (SMAW) welding, and often MIG (GMAW) or even DC TIG (GTAW) welding for thinner materials. This versatility means an owner of a single portable mini welding machine can tackle different materials—from mild steel to stainless steel or aluminum—by simply changing the torch, electrode, or wire feed setting. Such flexibility was previously difficult to find in such a compact form factor, enhancing the value proposition of a portable mini welding machine for users with diverse but intermittent needs.

Primary applications for the portable mini welding machine are found in light fabrication, repair, and creative work. Common uses include fixing metal furniture, automotive body panels, garden tools, or fencing. Artists and sculptors utilize the precision of a portable mini welding machine to assemble metal artwork. The equipment is also valuable for educational purposes in vocational training or for makerspaces, where its user-friendly design and safety features provide an introduction to welding fundamentals. In these contexts, the portable mini welding machine serves as an enabling tool, allowing users to complete metal joining tasks without investing in larger, more complex industrial systems.

The market for the portable mini welding machine is expected to grow, supported by trends in home improvement, customization, and small-scale manufacturing. Future iterations may see further miniaturization, increased battery compatibility for truly cordless operation, and enhanced connectivity for parameter guidance via mobile applications. While not intended to replace heavy-duty industrial welding machines, the portable mini welding machine has effectively carved out a substantial niche. It democratizes access to welding technology, empowering a new generation of users to undertake metalworking projects with a convenient, capable, and affordable tool. The sustained interest in this product category underscores a demand for professional-grade functionality in a compact, user-oriented format.

English

English русский

русский Français

Français Español

Español