Across industries and in countless daily tasks, a quiet revolution is taking place in the design of manual equipment: the integration of the labor-saving handle. This is not a specific product, but a design philosophy applied to the point where human force meets a tool. A labor-saving handle is engineered to reduce the physical effort, strain, and time required to perform repetitive or demanding manual operations. By applying principles of ergonomics, leverage, and mechanical advantage, these handles transform strenuous work into more manageable activity, enhancing productivity, improving safety, and reducing user fatigue.

The core function of a labor-saving handle is to optimize the transfer of human energy into productive work. Traditional straight handles on tools like shovels, brooms, or trolleys often force the user into awkward postures, concentrating stress on the back, shoulders, and wrists. A well-designed labor-saving handle changes this dynamic. It might feature a contoured grip that fits the hand naturally, a bent or angled shaft that promotes an upright posture, or a secondary grip point that allows for two-handed power with better body mechanics. The goal is to align the tool with the body's natural strength and movement patterns, making the work feel easier and less taxing.

The application of the labor-saving handle principle is remarkably diverse. In gardening, a shovel with a curved, D-shaped labor-saving handle allows for better leverage when digging, reducing back strain. In material handling, a pallet truck with a vertical pumping labor-saving handle lets an operator raise a heavy load with a series of comfortable arm motions instead of strenuous back bending. In janitorial work, a mop with a pivoting labor-saving handle enables efficient wringing without requiring the user to kneel or use excessive grip strength. Even in recreational equipment like fishing rods or golf clubs, ergonomic handles are a form of labor-saving handle, designed to improve control and reduce muscle fatigue during prolonged use.

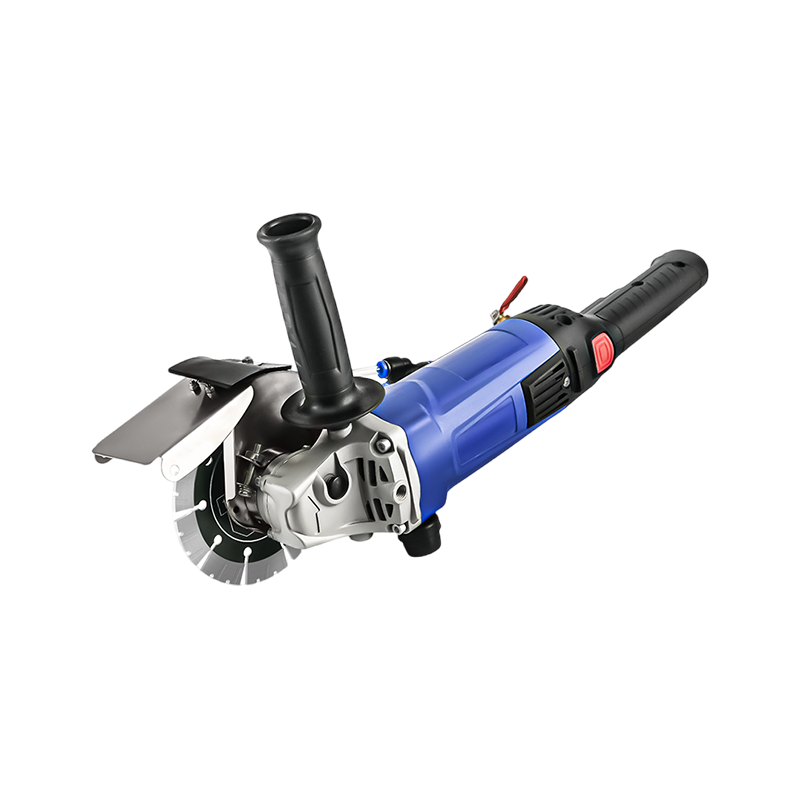

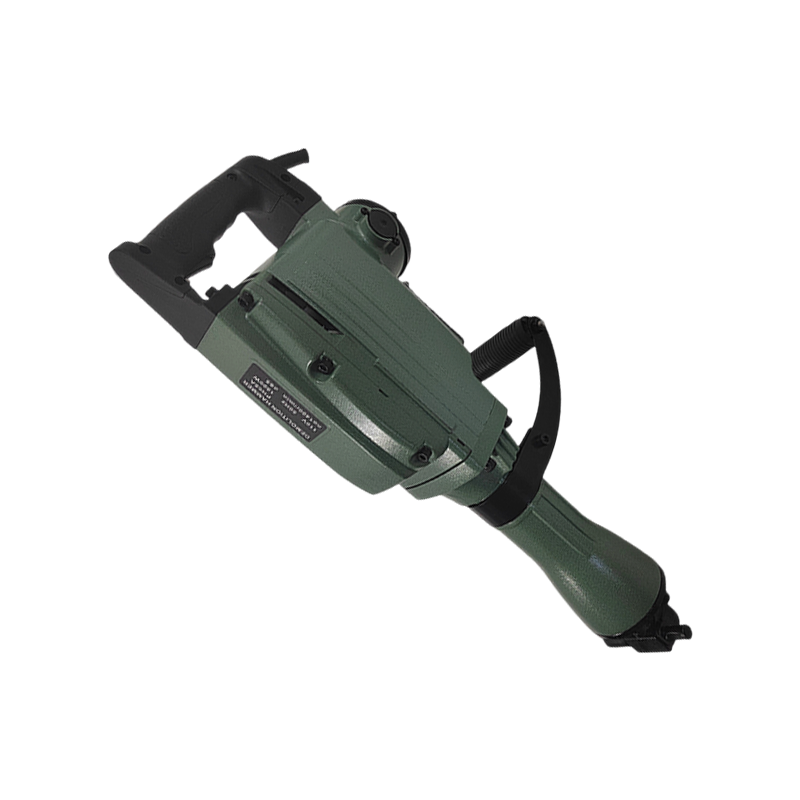

Mechanical innovation often elevates a simple labor-saving handle into a more sophisticated force-multiplying device. Ratcheting mechanisms are a prime example. A socket wrench with a ratcheting labor-saving handle allows a user to turn a fastener by swinging the handle back and forth in a confined space, eliminating the need to lift and reposition the tool with every turn—a significant efficiency gain. Similarly, a labor-saving handle on a pipe threader or a cable puller incorporates gearing to multiply the applied force, enabling one person to perform tasks that would otherwise require multiple workers or powered equipment.

The evolution of the labor-saving handle will continue to blend smart materials with human-centered design. We may see wider use of lightweight, vibration-dampening composites, adjustable handles that can be customized for different users or tasks, and even passive hydraulic or spring-assist systems integrated into the handle structure to further reduce effort. The integration of basic sensors to provide feedback on grip force or technique is another potential frontier. Ultimately, the labor-saving handle exemplifies a profound understanding that the impactful improvements often come not from replacing human labor, but from thoughtfully augmenting it, designing the interface between person and task to be as intuitive, efficient, and sustainable as possible.

English

English русский

русский Français

Français Español

Español