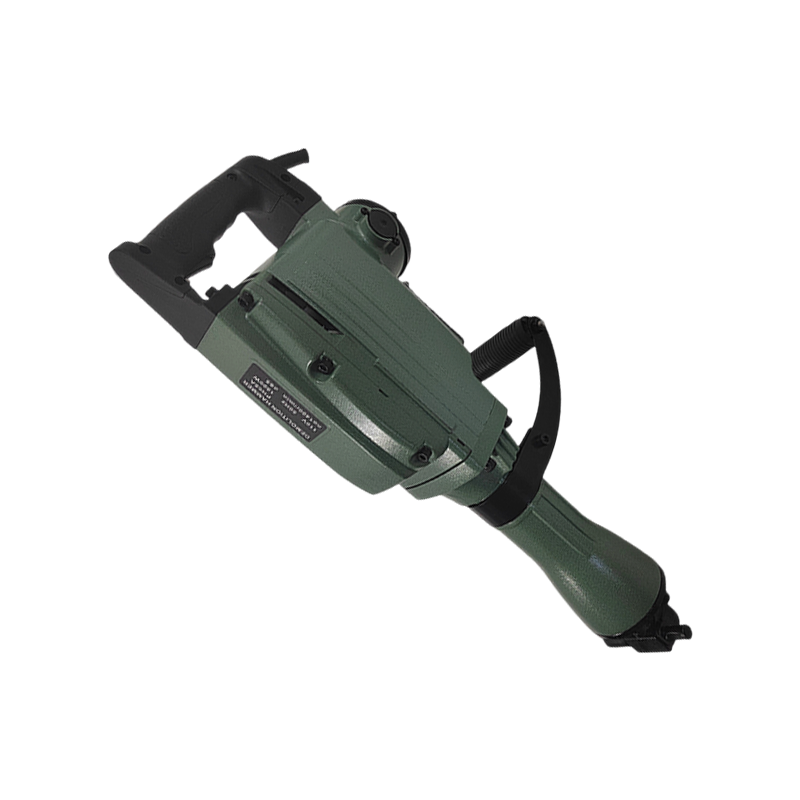

The need for robust, reliable metal joining in remote locations, on construction sites, and in maintenance scenarios often requires equipment that prioritizes durability, simplicity, and mobility. Meeting this specific demand is the Portable Stick Welder, a specialized category of arc welding machine designed for Shielded Metal Arc Welding (SMAW). Known for its straightforward operation and ability to handle challenging conditions, the Portable Stick Welder is a fundamental tool for welders, farmers, ranchers, and repair technicians who require a self-contained welding solution that can be easily transported to the job, whether in a field, a factory floor, or a home workshop.

The core function of a Portable Stick Welder is to generate the electrical current needed to sustain an arc between a consumable, flux-coated electrode (the "stick") and the metal workpiece. The machine takes input power—typically from a standard single- or three-phase outlet or from a generator—and provides a controllable DC or AC output. The welder adjusts the amperage based on the electrode diameter and metal thickness. When the electrode touches the workpiece and is quickly withdrawn, an arc is established, melting the electrode's metal core and the base metal to form the weld pool. The flux coating disintegrates, creating a protective gas shield and a layer of slag that covers the weld as it cools, protecting it from atmospheric contamination.

The defining characteristic of a true Portable Stick Welder is its emphasis on transportability and resilience. Modern units achieve this primarily through inverter technology. An inverter-based Portable Stick Welder converts incoming AC power to DC, then uses fast-switching electronics to create the desired welding output. This results in a machine that is dramatically smaller, lighter (often under 20 pounds), and more energy-efficient than traditional transformer-based welders of similar output. This compact size and weight make it genuinely portable, allowing it to be carried by its handle to wherever it is needed. These machines are also built with rugged casings to withstand job-site dust, moisture, and occasional impacts.

The application of a Portable Stick Welder is ideal for a wide range of outdoor and repair tasks. It is the go-to machine for structural steel work in construction, pipeline welding, and farm equipment repair, where wind can disperse shielding gas used in other processes. Its simplicity makes it a preferred choice for welding rusty, painted, or dirty metals that would challenge more sensitive processes like MIG or TIG. Hobbyists and DIY enthusiasts also favor the Portable Stick Welder for its low cost of entry, small required accessories (just the machine, cables, electrodes, and a helmet), and its effectiveness on common materials like mild steel. The ability to operate from a generator makes it indispensable for remote repairs where grid power is unavailable.

Current trends in Portable Stick Welder design focus on enhancing user experience, expanding capability, and improving durability. Many new models feature digital displays for precise amperage setting, hot start functions to prevent the electrode from sticking to the workpiece on ignition, and arc force control to stabilize the arc in various positions. Some inverter-based Portable Stick Welder units are now multi-process machines, offering Stick welding capability alongside optional TIG and even DC MIG welding functions, increasing their versatility for mobile service trucks. As infrastructure ages and field-based fabrication remains essential, the Portable Stick Welder continues to be a vital asset. Its evolution from a heavy, simple transformer to a lightweight, feature-rich inverter machine ensures it remains the lots of accessible and dependable welding solution for tackling tough jobs wherever they are found.

English

English русский

русский Français

Français Español

Español