Welding plays a crucial role in various industries, offering a method for joining materials with heat and pressure. In recent years, the evolution of welding machines has provided professionals and hobbyists with an array of tools suited for different applications. Among these, handheld electric welders, electric pipe welding machines, and electric stick welders stand out for their versatility, efficiency, and ease of use.

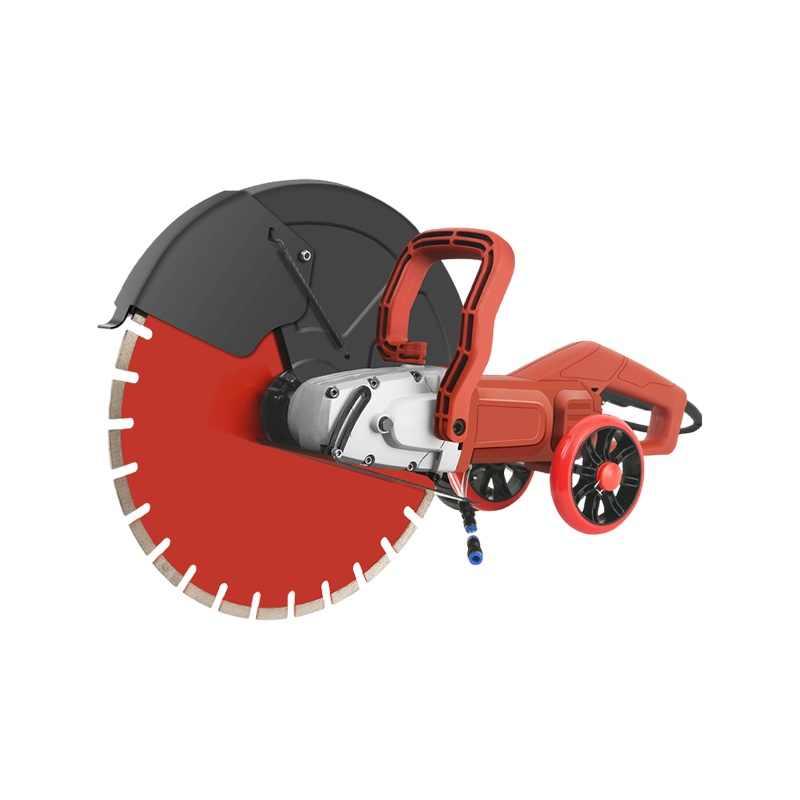

The handheld electric welder is a compact and portable tool designed for small to medium-sized welding tasks. This type of welder is particularly favored in industries where mobility and convenience are important. Its lightweight design allows it to be easily transported to various job sites, making it ideal for construction, maintenance, and repair work. Handheld electric welders typically use a variety of welding rods to handle different materials, including steel, aluminum, and other metals.

One of the key benefits of handheld electric welders is their simplicity and user-friendly nature. Even individuals with limited welding experience can achieve good results with the proper technique. These welders are versatile, capable of performing a wide range of welding applications, from home repairs to industrial maintenance. Their affordability and portability make them a popular choice for both professional welders and DIY enthusiasts.

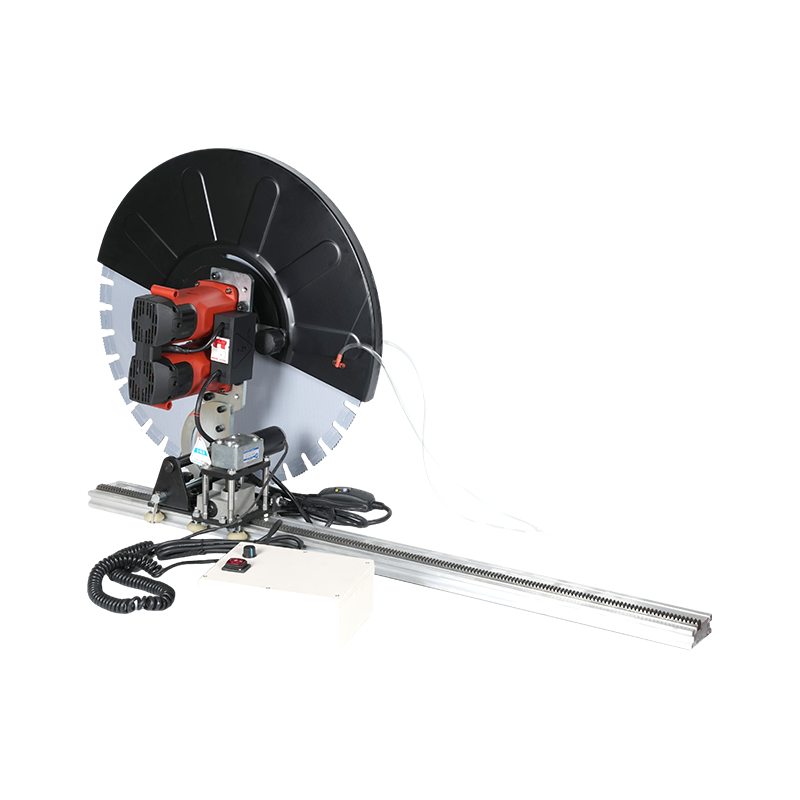

Electric pipe welding machines are designed specifically for welding pipes in industries such as construction, oil, gas, and water supply. These machines are built to provide precise control over the welding process, ensuring strong, durable joints in pipes that may carry high-pressure fluids or gases. Unlike handheld welders, electric pipe welding machines are often used in environments where pipes are pre-positioned and require a specialized tool to ensure proper alignment and weld integrity.

One of the advantages of electric pipe welding machines is their ability to handle larger pipe diameters and thicker materials. These machines typically feature advanced controls that allow the welder to adjust parameters such as temperature, speed, and voltage for different pipe sizes and material types. The precision offered by these machines is essential for preventing leaks, ensuring that the welds remain strong under pressure. While electric pipe welding machines are larger and less portable than handheld models, their specialized design makes them indispensable in pipe welding applications.

Electric pipe welding machines also offer greater consistency in their welds, reducing the risk of human error. This makes them particularly useful in industries where safety and quality are paramount, such as in the construction of pipelines for transporting oil, gas, or water. The ability to automate certain parts of the process, such as controlling the welding speed, ensures that the welds are uniform and meet industry standards.

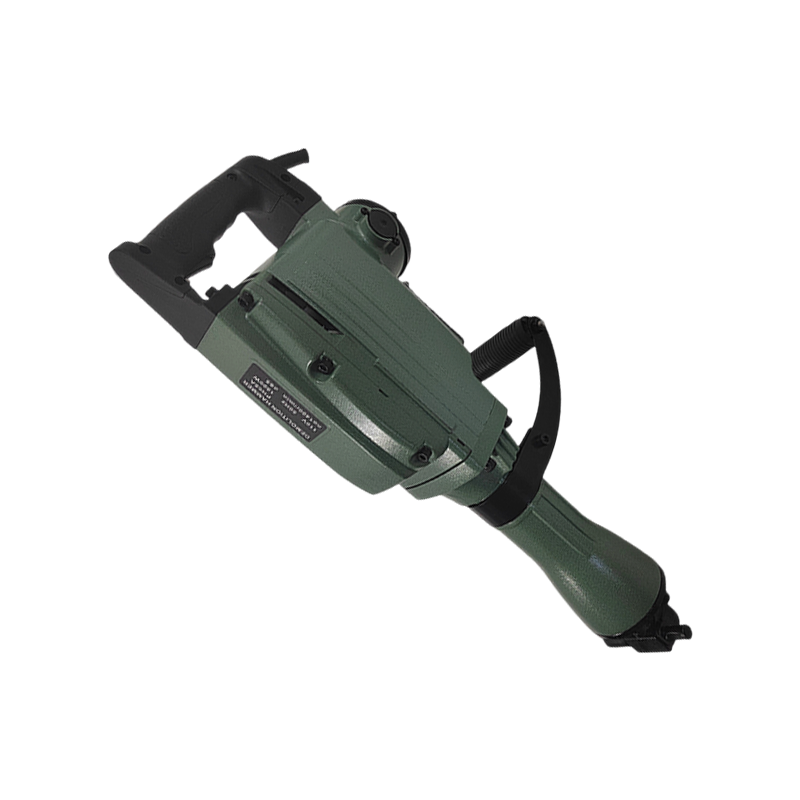

The electric stick welder, also known as the MMA (Manual Metal Arc) welder, is one of the commonly used welding machines due to its versatility and adaptability. This machine uses a consumable electrode to create a weld between two pieces of metal. It is ideal for use in heavy-duty applications, such as in the construction of steel structures, shipbuilding, and manufacturing.

Electric stick welders are known for their ability to work on a variety of metals, including steel, stainless steel, and cast iron. The process is simple, and the welder can easily change the electrode for different types of material. This flexibility makes the electric stick welder suitable for a wide range of welding tasks, both in the shop and on-site. Stick welders are also able to produce strong, high-quality welds, making them a reliable tool for demanding applications.

English

English русский

русский Français

Français Español

Español