The tool and equipment industry is seeing growing demand for labor-saving handle designs that reduce user fatigue while improving efficiency. Labor-saving handles are being incorporated into a wide range of products, from garden tools to industrial equipment, offering ergonomic benefits that make repetitive tasks less strenuous. These innovative handle designs combine advanced materials with biomechanical engineering to less strain on users' hands, wrists, and arms during extended use.

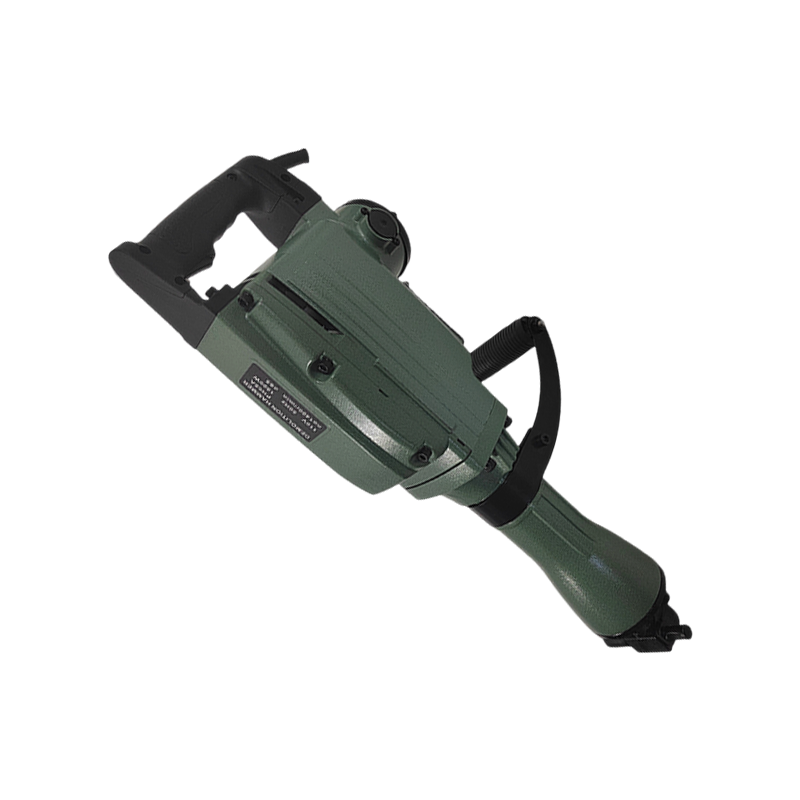

Recent developments in labor-saving handle technology focus on optimizing weight distribution and grip geometry. Many new designs feature contoured shapes that naturally align with the user's hand position, reducing the force required for operation. Labor-saving handles often incorporate vibration-dampening materials that absorb shocks and vibrations, particularly valuable for power tools and machinery. These improvements help prevent common workplace injuries while maintaining tool control and precision.

The agricultural sector has embraced labor-saving handle technology for various farming implements. Tools with specially designed labor-saving handles allow farmers and gardeners to work longer with less fatigue. Many modern gardening tools now feature rotating or pivoting labor-saving handles that maintain proper wrist alignment during digging, pruning, or raking motions. These ergonomic improvements are making outdoor work more comfortable for both professionals and hobbyists.

Industrial applications for labor-saving handles continue to expand across manufacturing and construction environments. Heavy-duty tools equipped with labor-saving handles help workers maintain productivity during extended shifts. Some advanced labor-saving handle designs incorporate counterbalance mechanisms that offset the weight of attached equipment, significantly reducing arm and shoulder strain. These innovations are particularly beneficial for workers performing overhead tasks or repetitive motions.

Material science advancements have enabled lighter yet more durable labor-saving handle constructions. High-performance composites and advanced polymers provide strength while small weight. Many contemporary labor-saving handles feature textured surfaces or non-slip coatings that improve grip in various weather conditions and when wearing work gloves. These material innovations enhance both comfort and safety during tool operation.

Healthcare professionals are recognizing the value of labor-saving handles in medical instruments and mobility aids. Surgical tools with ergonomic labor-saving handles allow for more precise control during lengthy procedures. Rehabilitation equipment incorporating labor-saving handle technology helps patients with limited strength or mobility maintain independence. These medical applications demonstrate the broad potential of thoughtful handle design across industries.

Consumer product manufacturers are increasingly adopting labor-saving handle principles for everyday items. Kitchen tools, cleaning equipment, and luggage now frequently feature designs that reduce hand and wrist strain. The growing awareness of ergonomic benefits has made labor-saving handles a selling point for many household products. This trend reflects consumers' increasing prioritization of comfort and long-term health in their purchasing decisions.

The sports equipment industry has implemented labor-saving handle technology in various training devices and performance gear. Athletic equipment with properly designed handles can help prevent overuse injuries while improving technique. Many fitness machines now incorporate labor-saving handles that adjust to different user heights and arm lengths, making workouts more effective and comfortable.

Future developments in labor-saving handle technology may include smart materials that adapt to individual users' grip strength and patterns. Research into pressure-sensitive surfaces could cause handles that provide feedback on proper technique. The integration of biometric sensors might offer real-time data on muscle strain and efficiency during tool use.

English

English русский

русский Français

Français Español

Español