In modern construction and renovation projects, creating precise channels and grooves in concrete and masonry walls is a common task. This process is often necessary for installing electrical conduits, water pipes, or communication cables. To accomplish this job efficiently and safely, many professionals rely on the Electrical Cement Wall Chaser Cutting Chasing Machine Tool. This specialized equipment provides a practical solution for creating uniform grooves while reducing manual labor and surface damage.

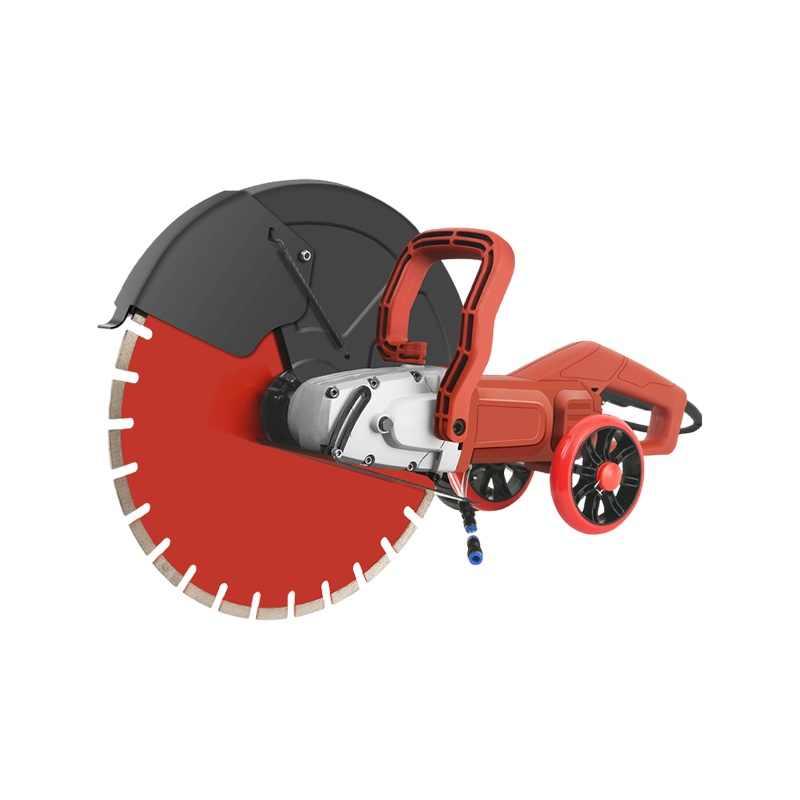

A Cement Wall Cutting Machine is specifically designed for cutting narrow, consistent channels into cement, brick, or stone surfaces. It uses rotating diamond-tipped blades to grind through hard materials, producing clean, straight lines without causing excessive dust or cracking nearby surfaces. These machines are especially useful for electrical wiring installation, plumbing, and other infrastructure work that requires concealed wall channels.

One of the key advantages of an Electrical Wall Chasing Tool is its precision. Unlike manual chiseling or angle grinders, this tool allows operators to set specific cutting depths and widths, ensuring consistent channel sizes throughout a project. This level of accuracy improves the appearance of finished installations and helps avoid unnecessary damage to structural materials.

The Electrical Wall Chasing Tool is commonly used by electricians, plumbers, and construction workers during building projects or remodeling work. Its ability to cut through tough materials like concrete and brick makes it suitable for creating recessed spaces for electrical outlets, switch boxes, and conduit runs. The tool’s adjustable blade spacing allows users to create custom-width channels for different types of installations.

Another important feature of a Cement Wall Cutting Machine is its dust control system. Many models are equipped with built-in dust extraction ports that can be connected to a vacuum, minimizing airborne dust and maintaining a cleaner, safer working environment. This is particularly beneficial when working indoors or in occupied buildings where controlling dust is a priority.

When selecting an Electrical Wall Chaser, key factors to consider include the machine’s cutting depth, blade size, and motor power. Deeper cutting capacity allows for larger conduits or pipes to be recessed into the wall, while adjustable blade settings offer flexibility for various channel widths. Motor strength ensures consistent cutting performance, especially when dealing with hard, reinforced materials.

The portability and ease of handling of an Electrical Wall Chasing Tool also make it an attractive option for construction professionals. Its ergonomic design and balanced weight distribution help reduce operator fatigue during prolonged use. Additionally, its compact size allows it to be used effectively in tight or awkward spaces where larger machinery might not fit.

Proper maintenance of a Cement Wall Cutting Machine is essential to ensure reliable performance and extend the life of the tool. Regularly checking the condition of the blades, cleaning dust extraction ports, and inspecting the power cable or battery (if cordless) will help keep the tool operating smoothly. Replacing worn blades promptly also maintains clean, efficient cutting results.

In addition to electrical and plumbing work, a Cement Wall Cutting Machine can be useful in creating decorative grooves or patterns in masonry surfaces. Architects and designers occasionally specify recessed lines in stone or brick walls for aesthetic purposes, and this tool provides a clean and controlled method for achieving these effects.

English

English русский

русский Français

Français Español

Español