The Electric Wall Board Slotting Cutter Machine is a specialized tool designed to improve the efficiency and precision of cutting slots in wall boards during construction and renovation projects. This machine is widely used by professionals in the building industry, helping to streamline the installation of electrical wiring, plumbing, and other systems that require channels within wall surfaces. The Electric Wall Board Slotting Cutter Machine combines power, accuracy, and ease of use, making it a valuable asset on any construction site.

One of the key advantages of the Electric Wall Board Slotting Cutter Machine is its ability to produce clean and consistent slots with minimal effort. Traditional methods of creating slots often involve manual chiseling or using less precise cutting tools, which can be time-consuming and result in uneven grooves. The electric slotting cutter machine automates this process, ensuring that slots are straight, uniform, and ready for installation work.

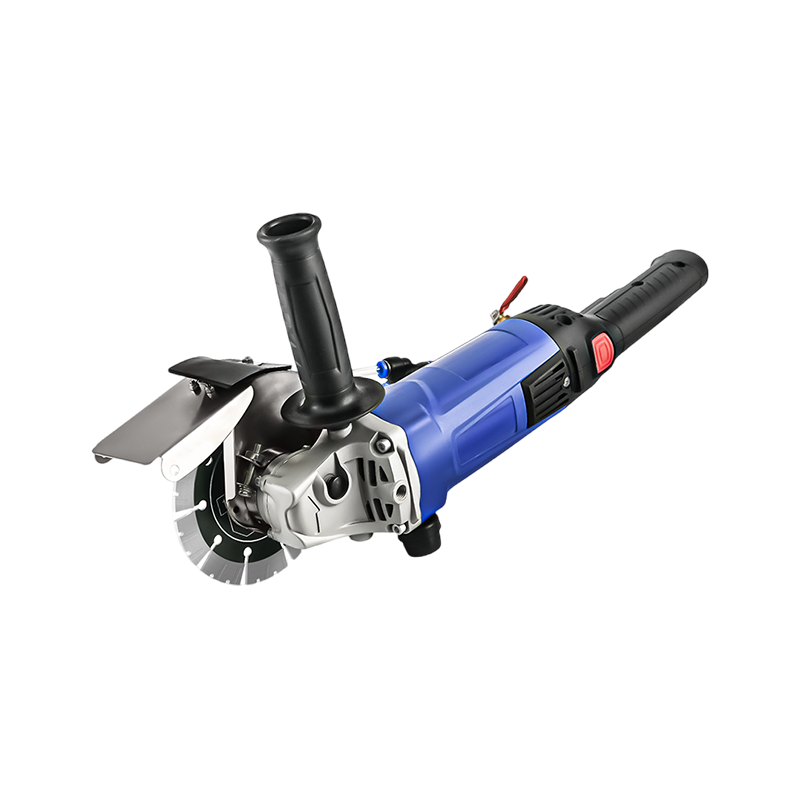

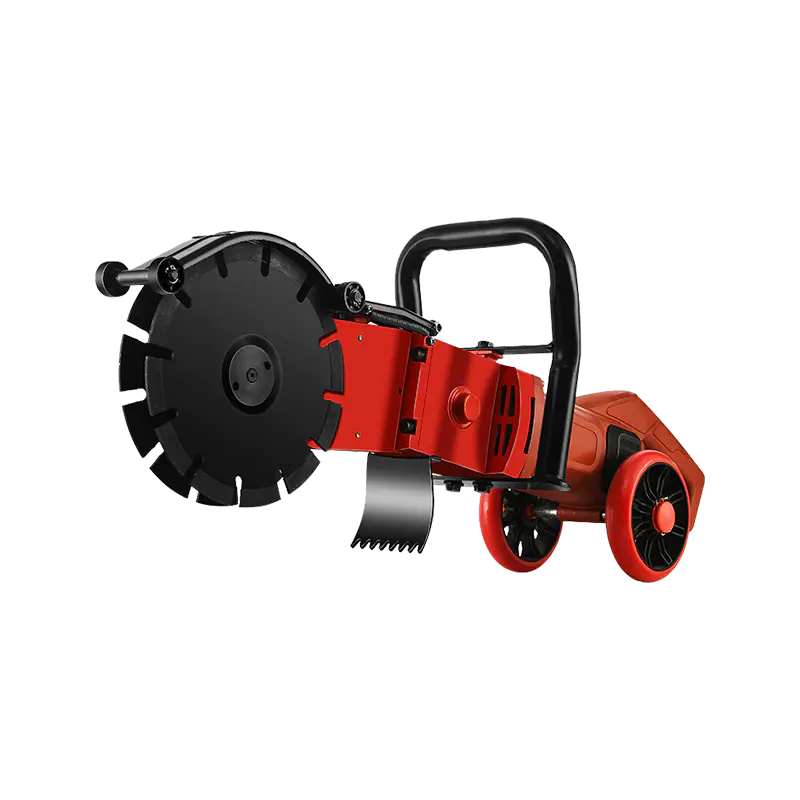

The design of the Electric Wall Board Slotting Cutter Machine typically includes adjustable cutting depths and widths, allowing users to customize the size of the slot according to the requirements of the specific project. This flexibility is essential when working with different wall materials such as drywall, plaster, or cement boards, which may demand varied slot dimensions for ideal results.

Safety is an important consideration in the operation of the Electric Wall Board Slotting Cutter Machine. These machines are generally equipped with protective features such as blade guards and ergonomic handles to reduce the risk of injury during use. Additionally, the electric motor runs smoothly, minimizing vibrations and providing better control over the cutting process. This ensures that operators can work more comfortably and confidently, even over extended periods.

The portability of the Electric Wall Board Slotting Cutter Machine also contributes to its usefulness. Many models are lightweight and compact, making it easier for workers to carry them around job sites or store them when not in use. The ease of transport is especially beneficial for professionals who need to move between different work areas or projects regularly.

Another benefit of the Electric Wall Board Slotting Cutter Machine is its efficiency. Speeding up the slotting process reduces overall project timelines and labor costs. Contractors can complete wall modifications more quickly and with fewer resources, which can improve profitability and customer satisfaction.

Maintenance of the Electric Wall Board Slotting Cutter Machine is generally straightforward. Regular cleaning of the blade and motor components, along with periodic inspections for wear and tear, helps ensure long-lasting performance. Many machines also feature easily replaceable blades, allowing users to maintain cutting quality without needing to invest in a new machine.

In terms of versatility, the Electric Wall Board Slotting Cutter Machine can be used in a variety of settings beyond traditional residential and commercial construction. For example, it is useful in renovation projects where walls need modification for new electrical outlets or plumbing installations. It also supports precise slotting in more specialized applications, such as HVAC system installations or soundproofing work.

The ease of use offered by the Electric Wall Board Slotting Cutter Machine is beneficial for operators of varying skill levels. Whether the user is a seasoned professional or someone with limited experience, the machine’s intuitive controls and adjustable settings make it accessible and practical. Training time is reduced, and the results are consistent, which helps maintain quality across projects.

English

English русский

русский Français

Français Español

Español